Rules and recommendations for setting bars

This procedure belongs to step 6 of the simple nesting workflow.

This procedure belongs to steps of the simple nesting workflow.

Bars that were incorrectly set are one of the most frequent cause for bad machining results. The rules and recommendations in this Help article will help avoid common mistakes.

- Open the Nesting view for setting bars with the following icon in the main toolbar:

General rules for setting bars

The following rules apply to nested objects in both discs and blocks.

Positioning bars in X- and Y-direction

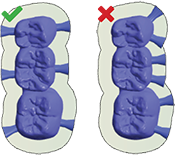

Place bars evenly on all sides

If you place bars on only one side, vibration during machining may occur. This can lead to the blank or tool getting damaged.

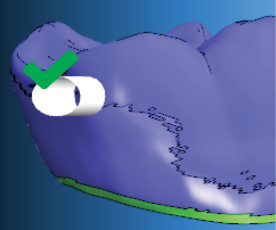

(): Bars on all sides of the object

Incorrect (right): Bars on only one side of the object

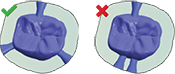

Place bars with sufficient distance from each other

If there isn't enough space between bars, the air nozzle of the spindle may not be able to blow off machining debris as required, which can damage the tool.

(): Bars with suitable distances between them

Incorrect (right): Bars without suitable distances between them

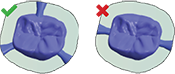

Set enough bars

You should at least set 3 bars for each object. Multi-unit-objects generally require 2 bars per unit. Otherwise, vibrations may occur during machining, which can lead to the blank or tool getting damaged.

(): Enough bars have been set

Incorrect (right): Too few bars have been set

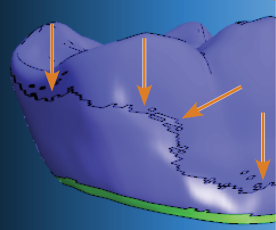

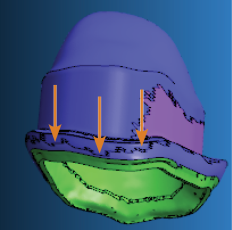

Positioning bars in Z-direction

- Position all bars on the equator. If the equator is on the prepline, position the bar approx. 1 mm above the equator.

You need to position all bars completely on the object.

The bar in the figure below is positioned too high. Only a part of the bar is positioned on the object.

The bar in the figure below is positioned too low. Only a part of the bar is positioned on the object. Additionally, the bar is positioned on the prepline.

The bar in the figure below is correctly positioned on the equator.

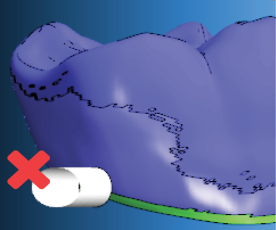

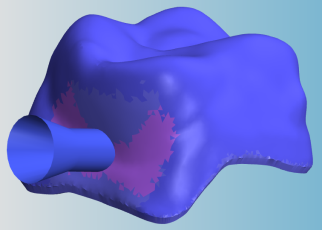

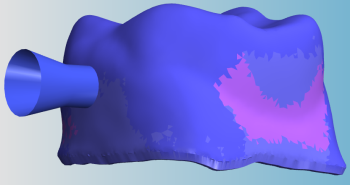

Placing bars on surfaces with sufficient material thickness

Always place bars on convex surfaces with sufficient material thickness. Otherwise, the stability of the bars may become too low and you will have to rework the object manually.

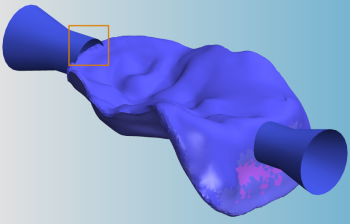

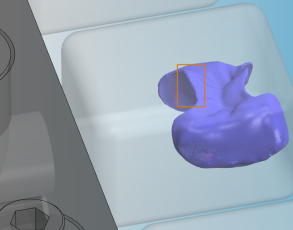

The following figure shows an inlay where the material thickness on the left side is not high enough to place a stable bar. The right side is suitable.

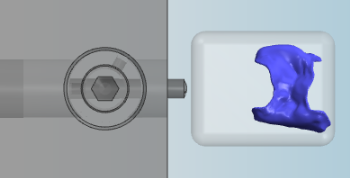

Customize objects in blocks

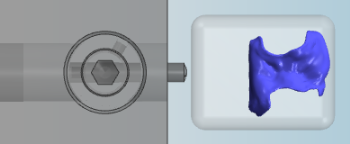

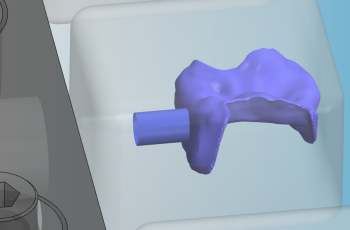

For blocks, the standard orientation of the objects may be unsuitable for the bar that runs from the object to the shaft of the block.

In this case, you need to rotate the object about the Z-axis so that you can place the bar on an surface with sufficient material thickness:

Use convex surfaces and avoid concave surfaces

Always place bars on convex surfaces because these surfaces can adequately support bars. The stability of bars placed on concave surfaces may be insufficient.

What's next?

If you are finished with nesting objects in the current blank:

If you are unsure whether you are finished nesting the current blank, see the simple and complete nesting workflow: