Key concepts and features

Milling without compressed air thanks to DIRECTAIR Technology

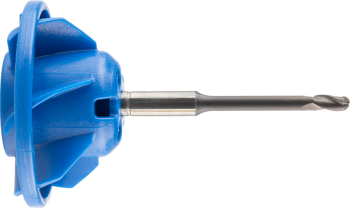

Instead of compressed air, the machine uses roughing tools with a propeller for chip removal during dry machining.

These AirTools keep the surface of the object clean during roughing and blow off the blank and working chamber after machining.

Wet and dry machining of blocks

Easy changeover between wet and dry machining by exchanging the containers.

Dry machining requires extra equipment![]() Physical component which must be obtained separately and which adds new functionality to your machine.. Extra equipment can be obtained from our customer service.

Physical component which must be obtained separately and which adds new functionality to your machine.. Extra equipment can be obtained from our customer service.

Automatic tool magazine for up to 6 tools

The machine can change tools automatically during machining, thus it executes jobs without your intervention.

Particularly low-maintenance and service-friendly

The number of regular maintenance tasks is minimal. See for yourself.

Exchange wear parts yourself without having to rely on customer service.