New functions | Improvement of an existing function | Bug Fixes

P4

This is a maintenance release.

Contains bug fixes.

(E5) Improvements

-

The test and calibration specimen have been optimized.

For milling, the following tools are used:

-

As before: P250-F1-40-T

-

Additionally: P200-R1-40

-

-

The default position has been adjusted.

(E5 machines from serial number E5ID5…) Calibration has been simplified

Thanks to newly installed temperature sensors, the software now adapts the processing to the temperature of the machine. This heat compensation means you no longer have to switch off the machine for 2 hours before calibrating.

New firmware version added

The following new firmware versions are now included in DentalCNC:

| E3 | E4 | E5 |

|---|---|---|

|

10.88.005 |

||

| N4+ | K5/K5+ | R5 | S1/S2/S5 | Z4 |

|---|---|---|---|---|

|

10.86.061 |

||||

NOTICE! Incorrect machining results due to incorrect firmware version

-

Install the most current firmware version for your machine right after updating DentalCAM & DentalCNC.

Highlights

(E5) New thermal compensation ensures even better results

The milling quality on E5 machines is further increased by adapting the machining strategies. A newly integrated thermal compensation can be used to compensate the expansion coefficients of the individual assemblies. This provides even more accurate results.

To utilize this benefit, do the following:

-

Switch off the machine for at least 2 hours. This makes it possible to set the thermal compensation correctly.

-

For best results, ensure an ambient temperature of 18 – 25 °C.

-

Update DentalCAM & DentalCNC to version 8.07.

-

Mill a calibration specimen, measure it and enter the values in DentalCNC.

New firmware version added

The following new firmware versions are now included in DentalCNC:

| E3 | E4 | E5 |

|---|---|---|

|

10.88.004 |

||

NOTICE! Incorrect machining results due to incorrect firmware version

-

Install the most current firmware version for your machine right after updating DentalCAM & DentalCNC.

DentalCAM & DentalCNC

(E4, Z4) 3Shape-Produce workflow with TRIOS Design Studio

3Shape Produce enables standardized data exchange between TRIOS Design Studio and DentalCAM.

3Shape Produce replaces the CAD/CAM integration of TRIOS Design Studio. A switch back to CAD/CAM integration is not planned.

For the changeover, vhf offers attractive deals. Your vhf reseller will be happy to help you.

The Essentials edition is now the improved ChairsideCAM

ChairsideCAM is a variant of DentalCAM with a specially adapted user interface for the chairside area. The user interface focuses on the typical steps in this workflow.

DentalCAM & DentalCNC are now available in Japanese

With immediate effect, the interface of both programs is also available with Japanese texts.

-

In the General application settings, select the entry for Japanese from the drop-down list Language.

Additional features and changes

DentalCNC

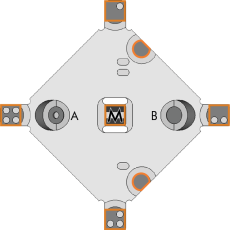

(E5) The test and calibration specimens have been optimized

Thanks to the adapted shape, the test and calibration specimen is milled faster.

Bug Fixes

DentalCAM

Possible collisions during disc machining eliminated

A collision of the tool with parts of the object could occur (among other things, when working with attachments).

This behavior has been corrected.

Possible collisions when machining drill holes eliminated

A collision of the tool with parts of the object could occur when machining holes.

This behavior has been corrected.

Possible collisions when machining bars eliminated

A collision of the tool with bars could occur when machining bars.

This behavior has been corrected.

Residual material quantity reduced

An unusually high amount of residual material could remain.

This behavior has been corrected.

Error during import of prefabricated abutments eliminated

Defective data import could result in incorrect assignments.

This behavior has been corrected.