Applies to: DentalCAM & DentalCNC 8.09 / 7.08

vhf tools and match codes

Tools structure

Main characteristics of tools

These characteristics determine the tools' behavior for different materials and applications. Therefore tools should only be used for the materials to which they are assigned via DentalCAM.

Number of teeth

There are:

-

Single tooth cutters These have a wide flute for good chip evacuation when machining soft materials and materials that tend to smear.

-

Multi-tooth cutters These have narrower flutes for machining hard materials that do not tend to smear. The wear is divided between the teeth, which makes these cutters more durable than single tooth cutters.

The most common tools used in vhfmachines are two-tooth cutters.

Tool length

The tool lengths of vhf tools differ according to the machine model.

| Non-precious metals | All other materials | |

|---|---|---|

|

E3 |

– |

60 mm |

|

E4, E5 |

– |

40 mm |

|

K4, K4 edition N4, N4+ Z4 |

32 mm |

35 mm |

|

K5, K5+ S1, S2, S5 R5 |

35 mm |

40 mm |

Coating

The tools are coated to make them harder than the usual hard metal tools. The most common coating is the diamond coating.

-

Due tof their hardness, coated tools have a longer tool life. Tool wear is significantly reduced. Built-up edges are prevented.

-

Tools for glass ceramics have a diamond grit, no diamond coating.

In the K1 – K4, the tool needs to establish an electrical contact with the measuring plate. Therefore, you cannot use diamond coated tools in the K1–K4.

Tool geometry

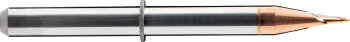

Milling tools

-

Radius cutters are milling tools with a rounded tool tip for machining 3D objects.

-

Used for roughing, finely finishing or carving out fissures.

-

Special case: If the tool tip is too small, the milling tool is not cylindrical but conical. This design ensures the needed stability of the tool.

-

Flat cutters are milling tools with a flat tool tip for machining 90° angles.

-

Flat cutters are used for the milling of connection geometries.

-

Used for smoothing of edges as well as roughing PMMA and wax.

-

Special case: Flat cutter with diamond teeth for machining fiber composites.

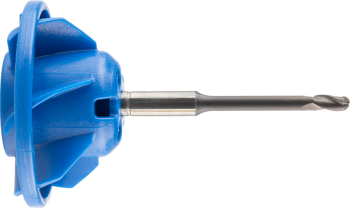

Grinding tools

Grinding tools differ in their tool tips.

-

Radius grinding tools are tools with a rounded tool tip for machining 3D objects.

-

Used for roughing, finely finishing or carving out fissures.

-

Special case: If the tool tip is too small, the grinding tool is not cylindrical but conical. This design ensures the needed stability of the tool.

Tool match codes

Tool match codes are unique combination of letters and numbers for tool identification. vhf tools are labeled as follows:

Material to be machined Cutting edge diameter – Geometry of the cutting edge No. of teeth Coating – Tool length

Tool geometry: Radius, flator torus

Special case: The C200-FXD-38 has an X instead of the number of teeth to indicate the diamond teeth.

AirTool: T in last place.

Example: Z100–R2D–40

Z – Zirconia

100 – 1.00 mm cutting edge diameter

R – Radius cutting edge geometry

2 – 2 teeth

D – Diamond coating

40 – 40 mm total length

Material to be processed Tool tip diameter – Tool tip geometry – Tool length

Geometry of the tool tip: Radiusor torus

Example: G100-R-35

G – Glass ceramics

100 – 1.00 mm tool tip diameter

R – Radius tool tip geometry

35 – 35 mm total length

Tool overview

DentalCAM 7 and DentalCAM 8 partially use different tools. See the corresponding columns of the tables below.

(U) Universal  |

|||||||

|---|---|---|---|---|---|---|---|

| Match code (4-axis except E4) | Match code (5-axis plus E4) | Cutting edge diameter | Tool geometry | Teeth | Coating | DentalCAM 7 | DentalCAM 8 |

|

U030–R2–35 |

U030–R2–40 |

0.3 mm |

Radius |

2 |

No |

Yes |

Yes |

|

U050–F2–35 |

U050–F2–40 |

0.5 mm |

Flat |

2 |

No |

Yes |

Yes |

|

U060–R2–35 |

U060–R2–40 |

0.6 mm |

Radius |

2 |

No |

Yes |

Yes |

|

U120-F2-35 |

U120-F2-40 |

1.20 mm |

Flat |

2 |

No |

Yes |

Yes |

(P) Wax and plastics (PMMA)  |

|||||||

|---|---|---|---|---|---|---|---|

| Match code (4-axis except E4) | Match code (5-axis plus E4) | Cutting edge diameter | Tool geometry | Teeth | Coating | DentalCAM 7 | DentalCAM 8 |

|

P100–R1–35 |

P100–R1–40 |

1.00 mm |

Radius |

1 |

No |

Yes |

Yes |

|

P100–R2–35 |

P100–R2–40 |

1.00 mm |

Radius |

2 |

No |

Yes |

Yes |

|

P200–R1–35 |

P200–R1–40 |

2.00 mm |

Radius |

1 |

No |

Yes |

Yes |

|

P200–R2–35 |

P200–R2–40 |

2.00 mm |

Radius |

2 |

No |

Yes |

Yes |

|

P250–F1–35 |

P250–F1–40 |

2.50 mm |

Flat |

1 |

No |

Yes |

Yes |

|

- |

P250-F1–40-T |

2.50 mm |

Flat |

1 |

No |

No |

Yes |

The T version of these tools is the AirTool.

Zirconia tools with light blue base have no diamond coating. Zirconia tools with dark blue base rings have a diamond coating.

(Z) Zirconia (ZrO2)   |

|||||||

|---|---|---|---|---|---|---|---|

| Match code (4-axis except E4) | Match code (5-axis plus E4) | Cutting edge diameter | Tool geometry | Teeth | Coating | DentalCAM 7 | DentalCAM 8 |

|

Z060–R2D–35 |

Z060–R2D–40 |

0.6 mm |

Radius |

2 |

Diamond |

Yes |

Yes |

|

Z100–R2–35 |

Z100–R2–40 |

1.00 mm |

Radius |

2 |

Standard |

Yes |

Yes |

|

Z100–R2D–35 |

Z100–R2D–40 |

1.00 mm |

Radius |

2 |

Diamond |

Yes |

Yes |

|

Z120–F2D–35 |

Z120–F2D–40 |

1.20 mm |

Flat |

2 |

Diamond |

Yes |

Yes |

|

Z200–R3–35 |

Z200–R3–40 |

2.00 mm |

Radius |

3 |

Standard |

Yes |

Yes |

|

Z200–R3D–35 |

Z200–R3D–40 |

2.00 mm |

Radius |

3 |

Diamond |

Yes |

Yes |

|

- |

Z200-R3D–40-T |

2.00 mm |

Radius |

3 |

Diamond |

No |

Yes |

The T version of these tools is the AirTool.

(C) Composites |

|||||||

|---|---|---|---|---|---|---|---|

| Match code (4-axis except E4) | Match code (5-axis plus E4) | Cutting edge diameter | Tool geometry | Teeth | Coating | DentalCAM 7 | DentalCAM 8 |

|

C100–R1D–35 |

C100–R1D–40 |

1.00 mm |

Radius |

1 |

Diamond |

Yes |

Yes |

|

C100–R2–35 |

C100–R2–40 |

1.00 mm |

Radius |

2 |

Standard |

Yes |

Yes |

|

C200–R1D–35 |

C200–R1D–40 |

2.00 mm |

Radius |

1 |

Diamond |

Yes |

Yes |

|

- |

C200-R1D–40-T |

2.00 mm |

Radius |

1 |

Diamond |

No |

Yes |

|

C200–R2–35 |

C200–R2–40 |

2.00 mm |

Radius |

2 |

Standard |

Yes |

Yes |

|

C200–FXD–35 |

C200–FXD–40 |

2.00 mm |

Flat |

|

Diamond |

Yes |

Yes |

The T version of these tools is the AirTool.

(M) Non-precious metals (Cobalt chrome / Titanium)  |

|||||||

|---|---|---|---|---|---|---|---|

| Match code (4-axis except E4) | Match code (5-axis) | Cutting edge diameter | Tool geometry | Teeth | Coating | DentalCAM 7 | DentalCAM 8 |

|

M060–R2-32 |

M060–R2–35 |

0.6 mm |

Radius |

2 |

Standard |

Yes |

Yes |

|

M100–R2-32 |

M100–R2–35 |

1.00 mm |

Radius |

2 |

Standard |

Yes |

Yes |

|

M120–T2–32 |

M120–T2–35 |

1.20 mm |

Torus |

2 |

Standard |

Yes |

Yes |

|

M200–R2–32 |

M200–R2–35 |

2.00 mm |

Radius |

2 |

Standard |

Yes |

Yes |

|

M200–R4–32(-C)* |

M200–R4–35(-C)* |

2.00 mm |

Radius |

4 |

Standard |

Yes |

Yes |

To use the -C version of these tools, you need to activate them in DentalCAM. Use designated finishing tool for secondary crowns

Tools for glass ceramics have a diamond grit, but no diamond coating. Therefore, their match codes do not contain a D.

(G) Glass ceramics (LiSi2)  |

|||||

|---|---|---|---|---|---|

| Match code (4-axis except E4) | Match code (5-axis plus E4) | Cutting edge diameter | Tool tip form | DentalCAM 7 | DentalCAM 8 |

|

G060–R–35 |

G060–R–35 |

0.6 mm |

Radius |

Yes |

Yes |

|

G060–T–35 |

G060–T–35 |

0.6 mm |

Torus |

Yes |

Yes |

|

G100–R–35 |

G100–R–35 |

1.00 mm |

Radius |

Yes |

Yes |

|

G120–T–35 |

G120–T–35 |

1.20 mm |

Torus |

Yes |

Yes |

|

G240–R–35 |

G240–R–35 |

2.40 mm |

Radius |

Yes |

Yes |

Specific tools are assigned to each of the color-coded tool magazines. The correct tool positions are shown on the touchscreen of the machine.

Wax and plastics (PMMA)

|

||

|---|---|---|

| Match code (4-axis except E4) | DentalCAM 7 | DentalCAM 8 |

|

U030–R2–35 |

Yes |

Yes |

|

U050–F2–35 |

Yes |

Yes |

|

U060–R2–35 |

Yes |

Yes |

|

U120-F2-35 |

Yes |

Yes |

|

P100-R1-35 |

Yes |

Yes |

|

P200-R1-35 |

Yes |

No |

Composites

|

||

|---|---|---|

| Match code (4-axis except E4) | DentalCAM 7 | DentalCAM 8 |

|

U030–R2–35 |

Yes |

Yes |

|

U050–F2–35 |

Yes |

Yes |

|

U060–R2–35 |

Yes |

Yes |

|

U120-F2-35 |

Yes |

Yes |

|

C100-R1D-35 |

Yes |

Yes |

|

C200-R1D-35 |

Yes |

Yes |

Zirconia

|

||

|---|---|---|

| Match code (4-axis except E4) | DentalCAM 7 | DentalCAM 8 |

|

U030–R2–35 |

Yes |

Yes |

|

U050–F2–35 |

Yes |

Yes |

|

Z060-R2D-35 |

Yes |

Yes |

|

Z100-R2D-35 |

Yes |

Yes |

|

Z120-F2D-35 |

Yes |

Yes |

|

Z200-R3D-35 |

Yes |

No |

Non-precious metals (Cobalt chrome / Titanium)  |

||

|---|---|---|

| Match code (4-axis except E4) | DentalCAM 7 | DentalCAM 8 |

|

M060-R2-32 |

Yes |

Yes |

|

M100-R2-32 |

Yes |

Yes |

|

M120-T2-32 |

Yes |

Yes |

|

M200-R4-32 |

Yes |

Yes |

Glass ceramics

|

||

|---|---|---|

| Match code (4-axis except E4) | DentalCAM 7 | DentalCAM 8 |

|

G060-R-35 |

Yes |

Yes |

|

G060-T-35 |

Yes |

Yes |

|

G100-R-35 |

Yes |

Yes |

|

G120-T-35 |

Yes |

Yes |

|

G240-R-35 |

Yes |

Yes |